NuCoMo-100

Contamination monitor for high background radiations

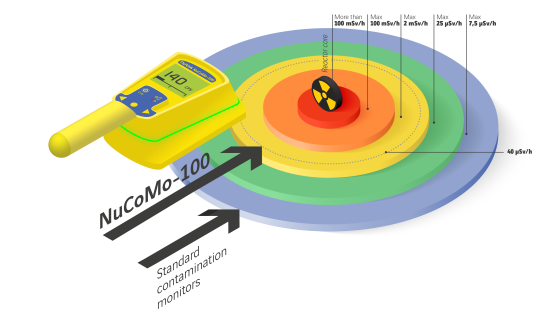

| Locations with a high background radiation – such as certain areas of nuclear power plants or sites of nuclear incidents – prohibit the use of most contamination measurement devices, while at the same time the risk of having contaminated surfaces is increased. This challenging task is where the newly developed NuCoMo-100 excels.

With the NuCoMo-100, β-contamination can be detected in a gamma background of up to 40 μSv/h when all the other standard contamination monitors are saturated with gamma counts. Most of all the user-friendly, handheld device allows to monitor significant contamination early-on and considerably mitigate the risk of dispersing radioactivity over the site.. |

|

The NuCoMo-100 has been developed as part of the collaborative R&D efforts with the CEA LIST. It uses a phoswich detector together with an innovative algorithm. Each scintillator of the phoswich has a different decay time constant allowing to perform

Pulse Shape Discrimination (PSD) between the beta and gamma pulses. Hence this state-of-the-art detector enables to discriminate the γ-background and measure only the β-contamination on the surface by comparing signals from two different detector layers. The user can choose between displaying the measurement results in cps, Bq, and Bq/cm². The possibility for expert users to additionally display either a histogram of the last 100s or a bar diagram of the current value in percent of the

alarm threshold increases the usability further. Two separate alarm thresholds can be set. The LED-ring flashes in yellow or red accordingly. Alarm thresholds can be adjusted for every nuclide and measurement mode specifically. The three measurement modes are the direct contamination measurement with only the NuCoMo-100 and the measurement of wipe tests and screening/ aerosol filters via the additional accessories. When plugged in, the software automatically recognizes the accessories and switches the menu accordingly.

The whole menu, measurement and calibration process is user guided. This allows to set numerous parameters, (de-)activate functionalities and use the integrated calibration menu by using only five function keys.

Need help?

If you have an enquiry about any of our products or services, please do not hesitate to give us your feedback or suggestions.